A few months ago I learned of digital cameras with integrated thermal printer for instant photo printing. As toy cameras aimed at kids, they have colorful exterior and low price to match. I decided it would be fun to get one. Play with the novelty for a while, then take it apart to learn its electronic guts. Perhaps it can be modified to satisfy one of my friend Emily’s suggestions for my Sawppy rover: instead of a robot arm with scientific instruments, maybe I can build a robot arm with a selfie camera. And with this design, I can instantly print the photo to share!

There are multiple vendors selling different implementations of the same basic concept. I decided on this particular unit (*) for two reasons. First, because it was the cheapest offering of the day and second, it has a camera sensor that can swivel 180 degrees to switch between front-facing (normal use) and back-facing (selfies). The swivel implies a long flex cable, and that should make rover integration easier.

A lot of accessories came bundled inside the box. Starting with five rolls of thermal paper to feed lots of prints. A pack of color markers let us perform colorization by hand, and a USB type A to type C cable for charging its internal rechargeable battery. Even a neck strap was included!

The camera enclosure was surprisingly well built. I had expected a few simple piece of ill-fitting injection-molded plastic, but it turned out to be more sophisticated than that. The eyes are separately molded pieces of white plastic instead of the sticker I had expected from product listing pictures. The ears are likewise separate pieces, as they are molded in a soft material. No weird plastic flashing and all pieces fit together well. This is pretty amazing quality considering the price point. I’ve paid more for stuff from Harbor Freight that weren’t made as well as this camera. I will be sad to break open the case later, but not enough to dissuade me from my original plan.

I got this device for its instant-print photo capability, but it can also record videos and there’s even a “Hungry” game that’s a weak implementation of the immortal snake game. It reminded me that, as primitive as the screen may be by modern standards, it is generations ahead of the black-and-white LCD used in classic Nokia brick phones.

Photo image quality and print quality were about as expected, which is to say quite poor and appropriate for an inexpensive toy. Certainly Canon won’t lose any sleep over this thing. But it’s definitely good enough to tell what the picture is supposed to be, and its unashamed low fidelity has an unique charm of its own. Given the price point I really can’t complain.

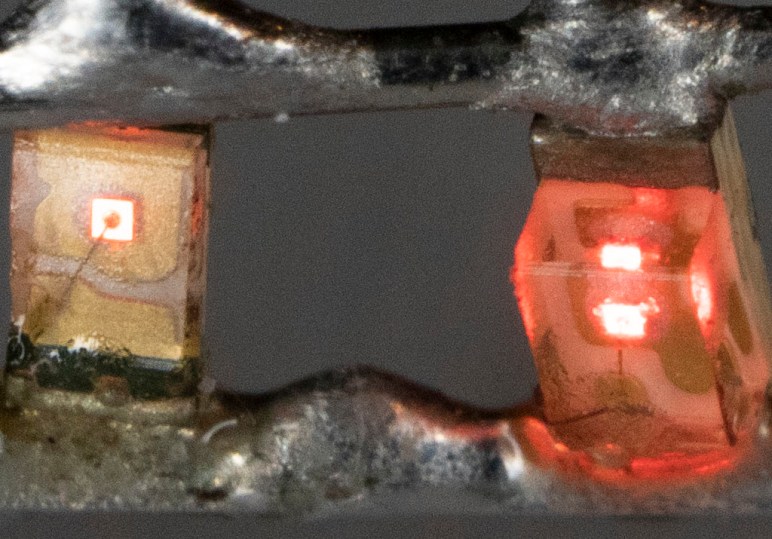

After playing with it for a few hours, print contrast was noticeably faded compared with earlier prints. I first thought maybe the device was designed fully expecting kids to get bored and lose interest quickly, and thus designed with a short service life in mind. But that’s inconsistent with bundling five rolls of paper! It then occurred to me I should try recharging the battery, and that turned out to be the answer: a topped off battery restored the full (if not very wide) range of contrast. Print quality a direct function of battery voltage? Wow. This thing is so spectacularly simplistic it has become its own special kind of awesome. It’s fun, I like it!

(*) Disclosure: As an Amazon Associate I earn from qualifying purchases.