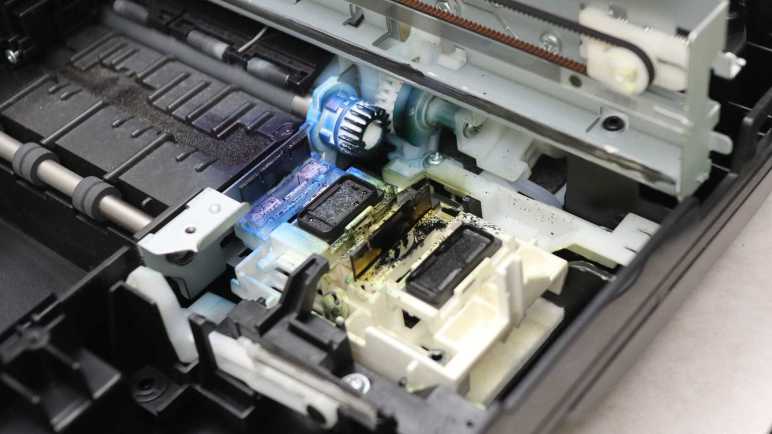

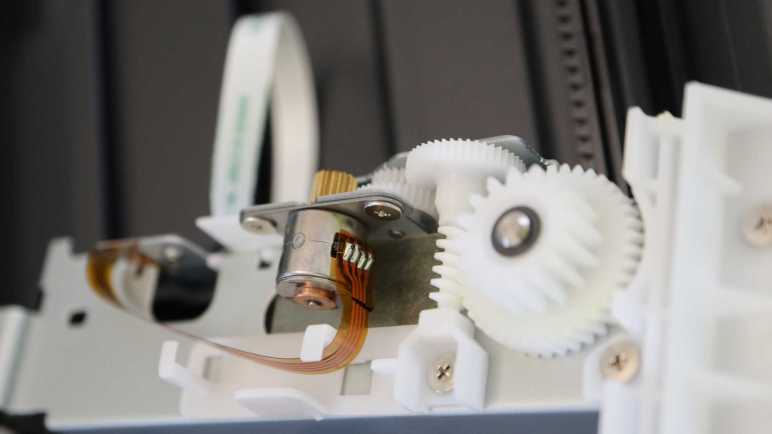

Working my way around the base of a Canon Pixma MX340 multi-function inkjet, removing panels and exposing components, I think I’ve reached a good stopping point. After disassembling the components behind the print head carriage motor, I have access to everything with an electric wire or cable attachment to the main control board. This is a good place to pause mechanical disassembly, and switch focus to probing electrically and see what I can learn. This marks the transition from phase 1 to phase 2 in my original 3-phase teardown plan.

There are still many fascinating mechanisms I have not yet explored, most of which are behind the print head parking area. It is home to at least two paper-handling functions: one to kick out the base of the paper feed tray, so the topmost sheet makes contact with the large central paper feed roller. Then another mechanism to turn that roller and feed a sheet into the print path. I also saw what looked like flexible tubes down there and I don’t know what they do yet.

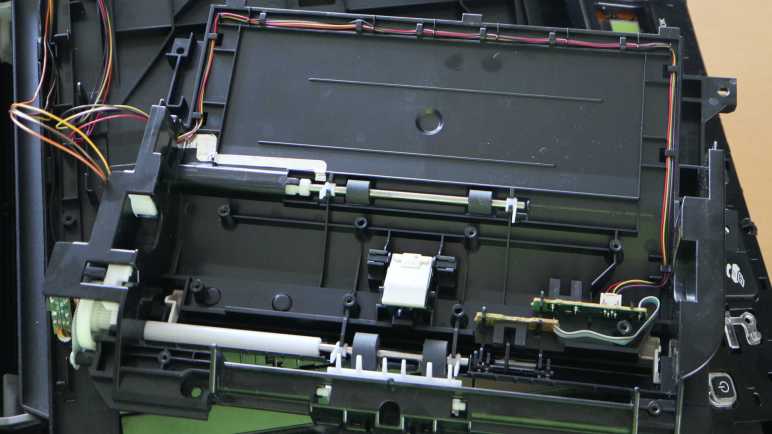

I think I know which screws I need to remove to access those mechanisms and get some answers, but I’m not sure if the printer will still function if I do. Right now, all the major components of this MX340 are laid out on a large desk (the scattered layout is too large to fit on my usual electronics workbench) and everything still runs. The document feeder can feed sheets of paper, the scanner can scan, and the inkjet can print. Taking the printer further apart may damage functionality, so I’ll postpone further disassembly until after I’ve learned what I can from electrically probing the printer while it is running.

What do I hope to learn? Well, I know I won’t understand everything. Part of why I have a collection of inkjet printers is that I had been waiting until I’ve learned enough to decipher all of the electronic details, letting the collection grow. But I’ve decided it’s OK if I can’t decipher everything. So I will scope phase 2 of my project with reasonable expectations and a plan.

This teardown ran far longer than I originally thought it would. Click here for the starting point.