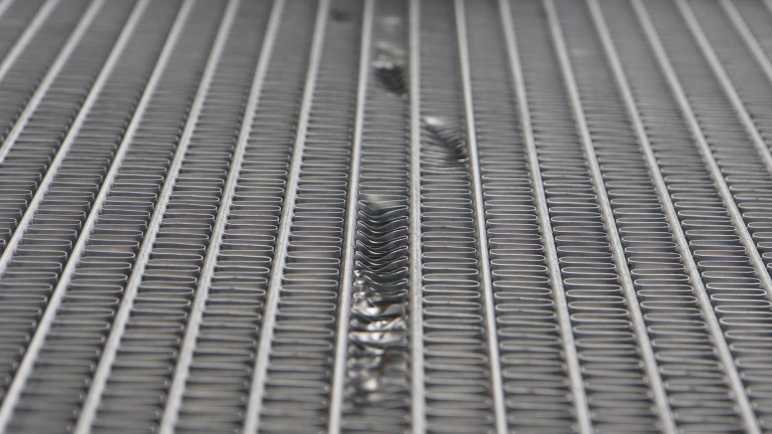

This blog serves as my project notebook, and for completeness I try to document my failures as well as my successes here for future reference. The header image came from testing my Sawppy rover wheel design to failure. Sometimes documenting my failure is hard to do, especially for problems whose solutions look obvious in hindsight. Once I solved it, I have a hard time articulating why it was ever difficult!

Most people tout their successes and de-emphasize their failures. I can respect their choice but I love seeing blooper reels both in and out of show business. A few days ago Boston Dynamics announced retirement of their hydraulically actuated Atlas humanoid research robot with a highlight reel of its history. Alongside Atlas accomplishments, the reel also included Atlas flailing and taking some bad spills.

This is only the latest in a series of impressive and occasionally amusing videos released by Boston Dynamics. Most videos are edited down to show only successful actions, because that’s what they want people to focus on. But their success rate are far below what these “best case scenario” edits imply. Anyone who worked with robots know how low general success rates are, and would notice all the scuff and scrapes visible on Atlas’ body to know Boston Dynamics is not immune. But other people lack such knowledge and would miss such indication of damage, to a point these videos are borderline misleading when viewed by the general populace That history is why I was very happy to see this “Fare to HD Atlas” video covering some failures on the route to success in a very impressive project.

That said, the best example of the genre remains “How Not to Land an Orbital Rocket Booster” from SpaceX. A compilation of many failures on their way to successfully landing boosters for reuse. Once considered impractical, now routine for SpaceX, but many millions of dollars had to go up in big fireballs in order to get there.