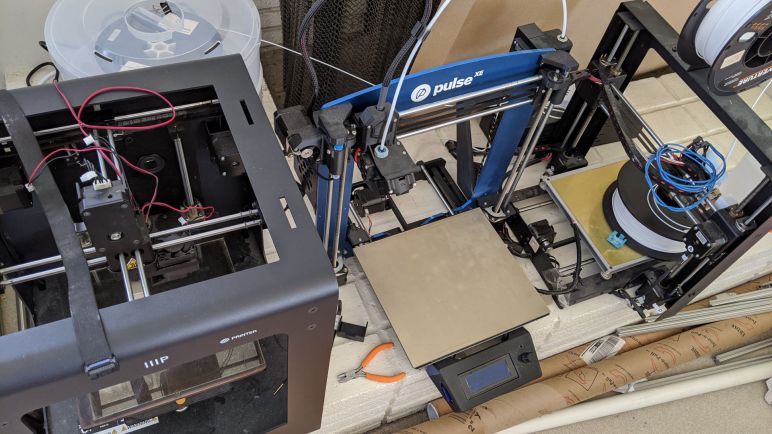

When I first got started in 3D printing, I was well aware of the trend for enthusiasts in the field to quickly find themselves with an entire flock of them. I can confirm that stereotype, as now I am in the possession of (most of) five printers.

My first printer, a Monoprice Select Mini, was still functional but due to its limitations I had not used it for many months. I had been contemplating taking it apart to reuse its parts. When I talked about that idea with some local people, I found a mutually beneficial trade: in exchange for my functioning printer, I traded it for a nearly identical but non-functioning unit to take apart.

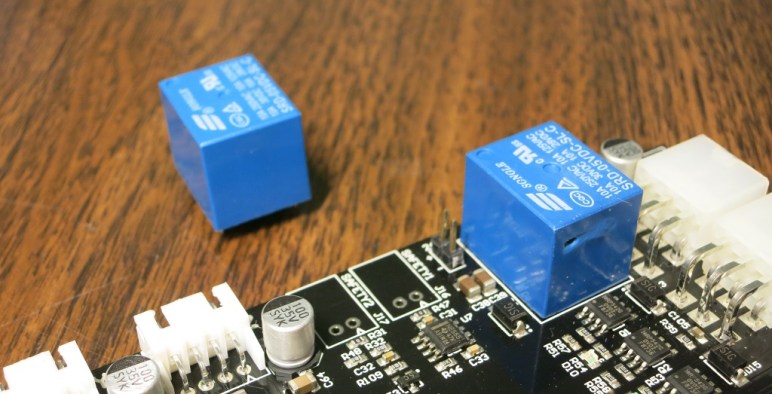

My second, a Monoprice Maker Ultimate, has experienced multiple electrical failures with an infamous relay, and I suspect those failures had secondary repercussions that triggered other failures in the system. It is currently not working and awaiting a control board upgrade.

My third printer, a Monoprice Maker Select, was very affordable but there were trade-offs made to reach that price point. I’ve since had to make several upgrades to make it moderately usable, but it was never a joyous ownership experience.

Those three printers were the topic of the tale of 3D printing adventures I told to Robotics Society of Southern California. One of my parting advise was that, once we get to the ~$700 range of the Maker Ultimate, there were many other solid options. The canonical default choice is a Prusa i3 and I came very close to buying one of my own several times.

What I ended up buying is a MatterHackers Pulse, a derivative of the Prusa i3. I bought it during 2019’s “Black Friday” sale season, when MatterHackers advertised their Pulse XE variant at a hefty discount. Full of upgrades that I would have contemplated installing anyway, it has performed very well and I can happily recommend this printer.

Why would I buy a fifth printer when I had a perfectly functioning Pulse XE? Well, I wouldn’t. I didn’t get this printer because it was better, I picked it up because it was free. I have some motion control (not 3D printing) projects on the candidate list and a retired partial Geeetech A10 printer may prove useful.

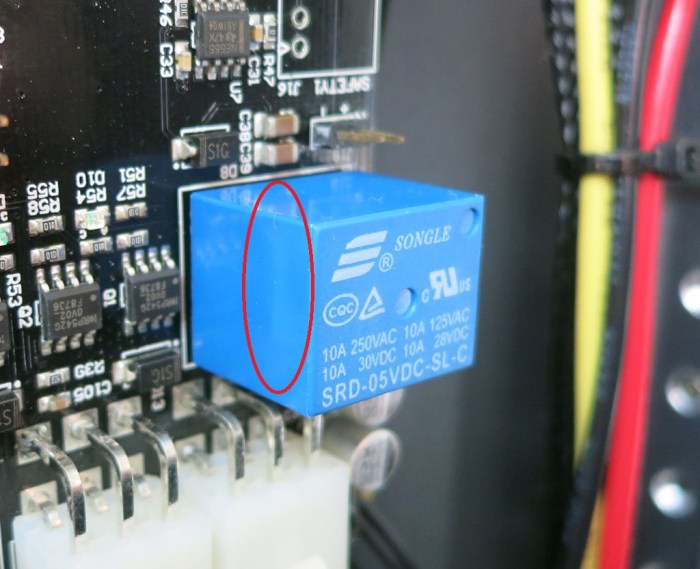

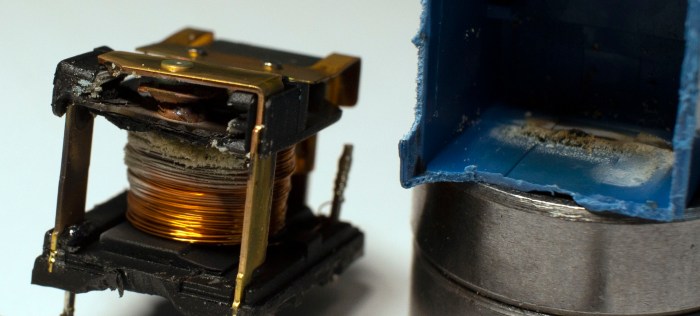

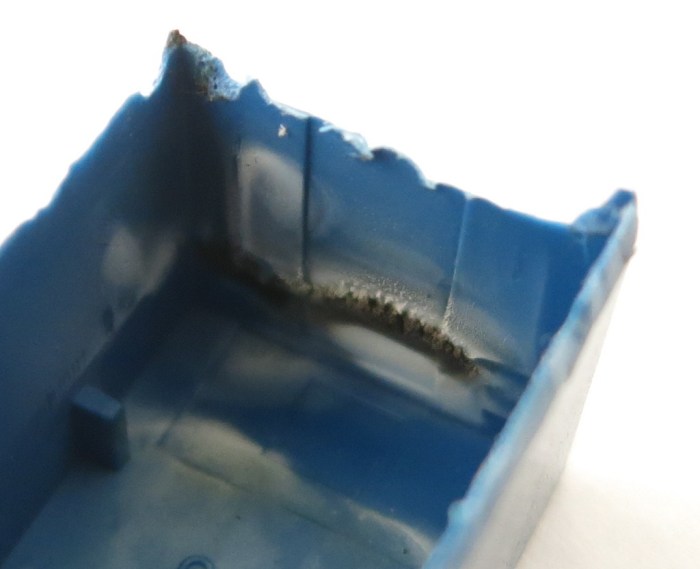

Looking at the inside of the just-removed case, we can see a lot of heat damage. Black char marks the hottest areas, and discolored white marked the rest.

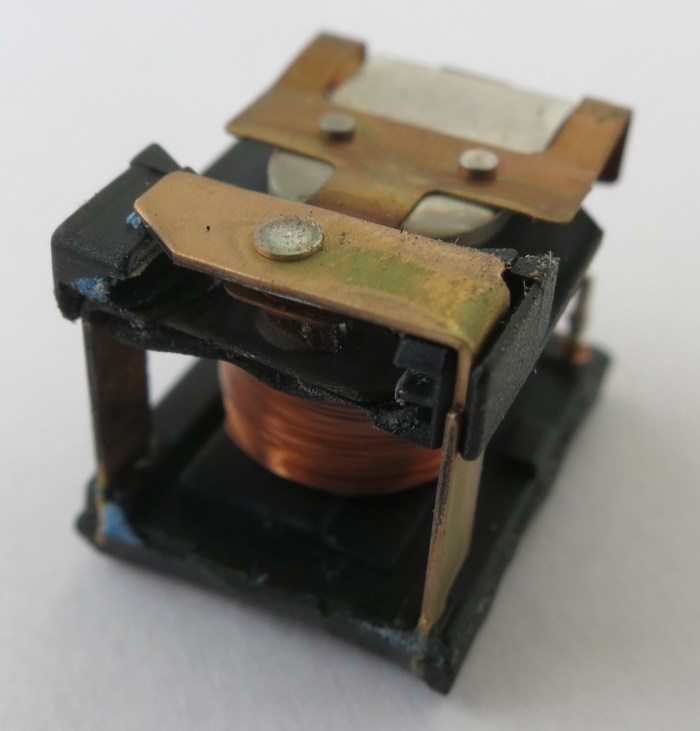

Looking at the inside of the just-removed case, we can see a lot of heat damage. Black char marks the hottest areas, and discolored white marked the rest. It’s a fairly straightforward relay, with the coil actuating an armature moving between contacts on either the plate above or below it. The armature+contact area is immediately behind the blacked charred bits of the case. And looking at the armature and contacts themselves, we see the relay died an unhappy death.

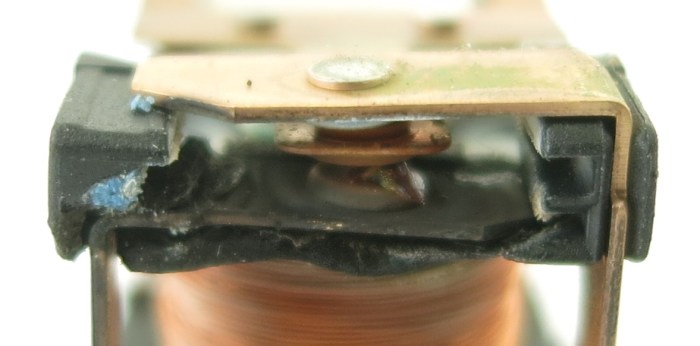

It’s a fairly straightforward relay, with the coil actuating an armature moving between contacts on either the plate above or below it. The armature+contact area is immediately behind the blacked charred bits of the case. And looking at the armature and contacts themselves, we see the relay died an unhappy death. Everything in the contact area is distorted and/or charred. There is a black plastic-feeling piece holding everything in position relative to each other, and it could no longer do its job with heat distorting it and moved things out of alignment. Between the armature and the bottom contact is a blob of melted something that looks vaguely like solder. The bits of blue visible are parts of the blue casing that has melted onto this assembly. While the top contact looks OK in this picture, the side facing the armature is just as blackened and charred as the visible face of the bottom contact. The armature itself is barely visible here but it is actually discolored and distorted near the contacts.

Everything in the contact area is distorted and/or charred. There is a black plastic-feeling piece holding everything in position relative to each other, and it could no longer do its job with heat distorting it and moved things out of alignment. Between the armature and the bottom contact is a blob of melted something that looks vaguely like solder. The bits of blue visible are parts of the blue casing that has melted onto this assembly. While the top contact looks OK in this picture, the side facing the armature is just as blackened and charred as the visible face of the bottom contact. The armature itself is barely visible here but it is actually discolored and distorted near the contacts.