I thought the LEGO Technic Unimog truck was an admirable model of the real truck both in appearance and mechanical detail, but I found the pneumatically operated crane arm accessory wanting. I kept my eyes open for another set, one that would revert to mechanical linear actuators and offer motorized controls on all axis of movement. My wish was granted by LEGO Technic Motorized Excavator (8043).

I was bemused when the manual started with a warning that we should not actually take the excavator to play in the dirt. Bah, spoilsports!

Both crane trucks included only a single motor and a complex gearbox with multiple clutches to redirect that power. In contrast, this set included four motors and a single selection clutch. That selection is actuated by one of the motors. The remaining three motors would do one of two jobs depending on that selection, for a total of six functions. When the clutch is set in one way, these three motors control excavator locomotion: left track forward/back, right track forward/back, and body pivot clockwise/counterclockwise. When the clutch is set the other way, these three motors control excavator arm motion: shoulder joint up/down, elbow joint in/out, and wrist joint for bucket scoop/release.

In hindsight, this instruction manual did not meet the usual bar of LEGO instructions. I encountered the first issue during arm assembly. It was physically impossible to mount the pair of blue pins as instructed. I had to shift them one position over for things to fit. The second issue I didn’t realize until after assembly: there weren’t any checkpoint tests. The Crane Truck instructions included a few tests of “turn this shaft, you should see movement in that shaft” nature, helping us verify we had assembled the gearbox correctly. This manual had nothing of that sort, so I didn’t notice my mistake.

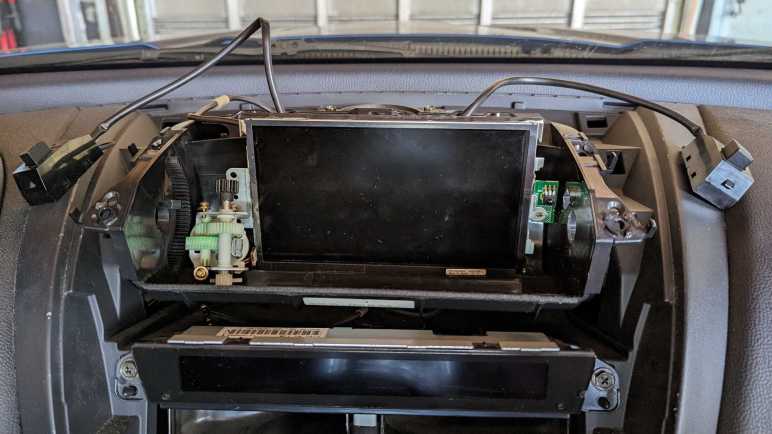

Once I completed construction, I was happy to see the gearbox internals exposed to view. For some reason, the product package designer tried to hide this fact, showing the excavator only from angles where we couldn’t see the exposed gearbox. I liked seeing the gears work! Which was good, because I immediately found that I couldn’t control shoulder joint elevation. The exposed gearbox allowed me to debug. Tracing forward from the spinning motor, and going backwards from the shoulder elevation actuators, I found where they were supposed to meet.

The mistake happened here in step 39. The instructions called out two of the gears because their orientation is important. I made sure I installed those two gears correctly, but I missed the fact there was a third gear I was supposed to install as well. Its orientation was not important, but it needed to be there!

I didn’t want to take everything apart in order to rewind back to step 39 out of 99 steps. I tried to be clever, selectively disassembling just what I thought I needed to access the short red shaft that was missing a gear. I felt pretty good about this process until I heard a dreaded plastic-on-plastic “clink!” sound of something falling out.

Gah! Where did you come from? Trying to be clever about installing a missing gear had allowed this gear to fall out the bottom. I turned the excavator over to see if I could figure out where it came from, and immediately learned this was a bad idea because I heard “clink, clink” of more parts falling out. I am digging myself a deeper and deeper hole here.

A cascading comedy of errors ensued as I took the excavator further and further apart. It seemed like every time I tried to put a part back where it was supposed to go, two more would fall out. But I eventually stabilized the situation, installed the gear that I missed the first time, and put everything back together in working order. I doubt I saved any time by trying to be clever, but looking on the bright side I now have a much better understanding of how this excavator fits together.

Once it was all put together and working, I am very happy with this set. I finally had a LEGO Technic set that motorized all the axis of motions necessary to replication movement of the real equipment the kit emulated. And even better, this kit is remote controlled via infrared so I’m not even flipping levers on the machine. I could send it on a journey across the room to scoop up loose piles of LEGO pieces and drop them somewhere else. This is the closest I’ve come to fulfilling the fantasy of 5-year-old me to operate construction equipment. The next obvious step is to rent some time on the real thing, but that’s beyond the scope of a LEGO nostalgia tour.

Naturally, a tinkerer’s brain would look at a great thing and think of ways to improve it. Hackaday recently featured a project by Brick Technology YouTube channel. It repurposed many pieces from this set but articulates the arm with a hydraulic system installed in an entirely different body. It’s pretty impressive! But I don’t think I’ll go down that path because it doesn’t address my gripes with LEGO Technic.